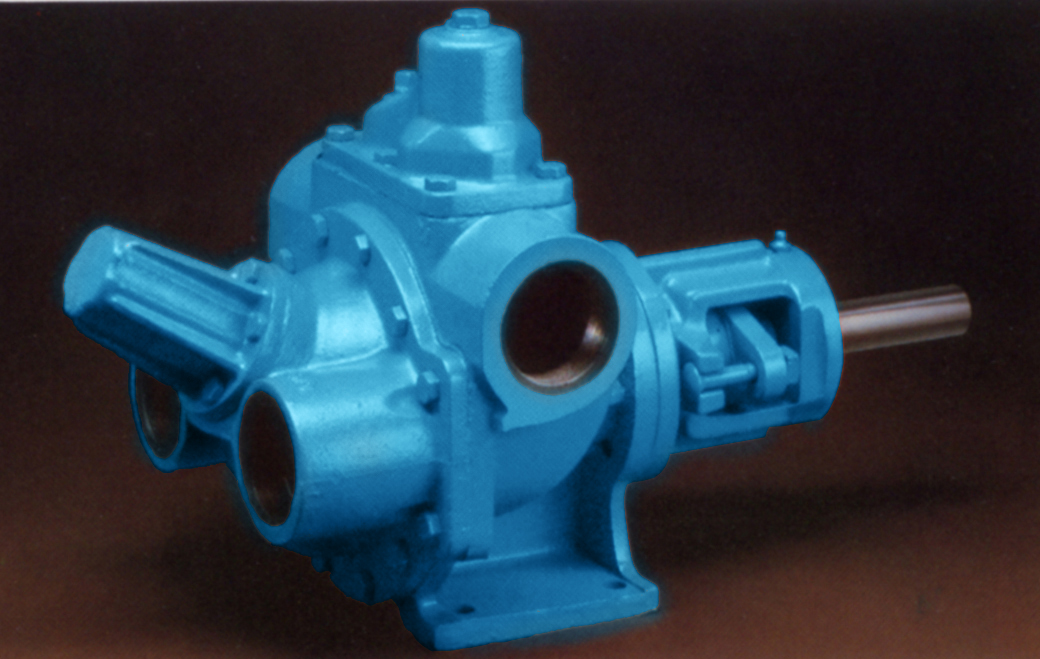

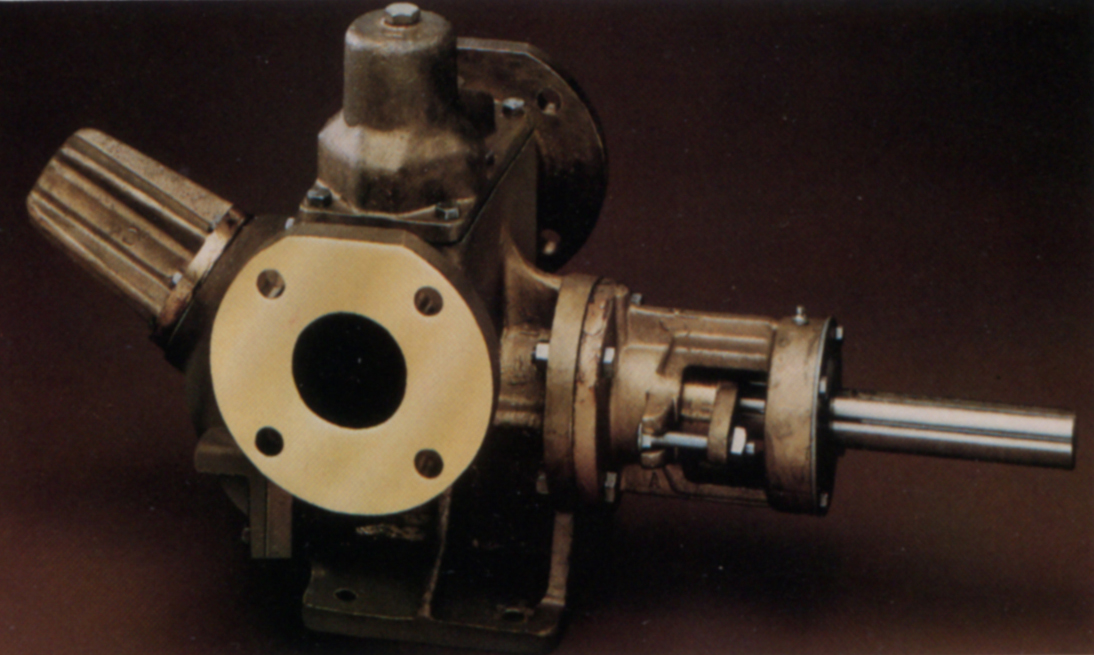

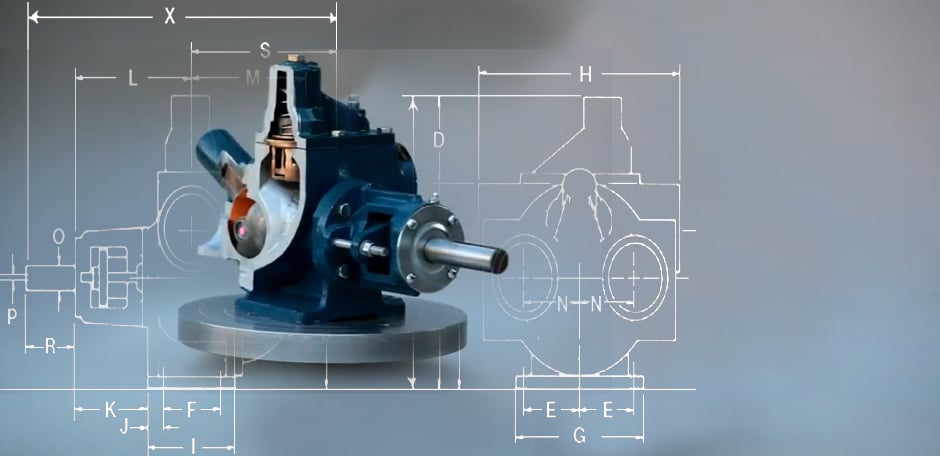

SEE WHAT MAKES GRANCO ROTARY BALL PUMPS RUN…

The secret is the unique, floating Granco rotor. Pivoted in a spherical housing, the rotor provides positive expulsion of fluid from the pump chamber directly into the line of flow. The simplicity of the Granco design provides excellent fluid displacement without the use of gears, blades, vanes, paddles, scoops, pistons, valves or stators.

And Run...

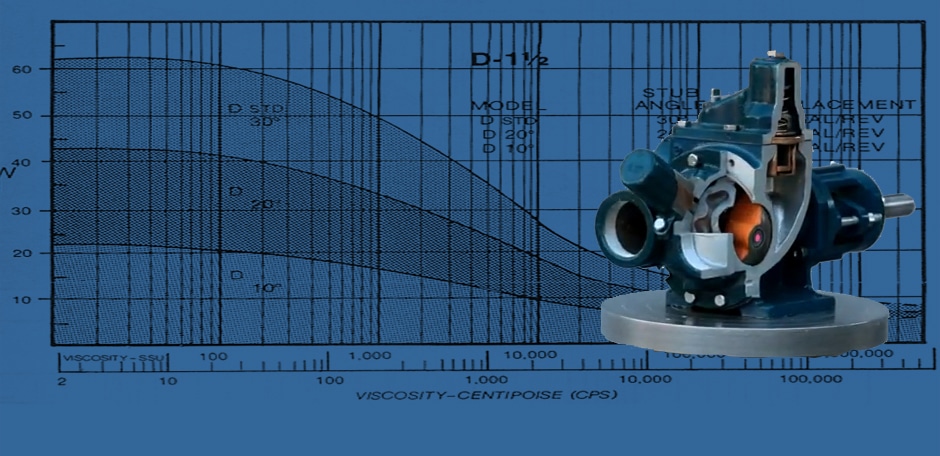

A standard Granco rotary ball pump can move a tremendous varieties of fluids with viscosities ranging from 30 to 1,000,000 SSU without modification of standard clearances. Product ranges include:

PETROLEUM – From solvents through crude and lube oils.

INDUSTRIAL – From water-based paints through caulking compounds.

EDIBLE – From vegetable oils through molasses and peanut butter.

And Run...

The Granco rotor has four large pumping chambers. These individual chambers are positioned so that incoming fluids flow directly to the heart of the rotor. Since fluids enter and exit the rotor cavities with less friction and less shear, the Granco pump displaces more product with greater efficiency than other designs. Gallon for gallon, Granco pumps will normally deliver more product at the same speed and require less horsepower than other positive displacement pumps.

And Run.

The performance of a positive displacement pump depends upon maintaining the tolerances of the pump mechanism. Operating speed attacks these tolerances. The floating Granco rotor minimizes metal to metal contact in the pump. The large cavities allow the Granco pump to operate at lower RPMs. These features combine to preserve the pump’s original tolerances. Thus the Granco pump will run slower and longer and require less ongoing maintenance.

Why Choose a Granco Pump?

Reversible Flow

The direction of flow in positive displacement pump designs depend on shaft rotation. Granco can provide flow in either clockwise or counter-clockwise direction by simply rotating the valve components 180 degrees. This simple adjustment will take only minutes and provides for the flow in either preferred direction. An arrow pointing to the inlet side is cast into our relief valve cover to confirm to the operator the correct inlet port.

Durable

Granco manufactures a full line of unique rotary positive displacement ball type pumps. In fact, it is the only ball type design being manufactured today. The simple ball and shaft design promotes durability because the pumping mechanism “floats” in the housing with no metal to metal contact. This design promotes years of durable and dependable service. The large rotating cavities provide slower speeds which maintains critical tolerances not seen in any other designs.

Adaptable Design

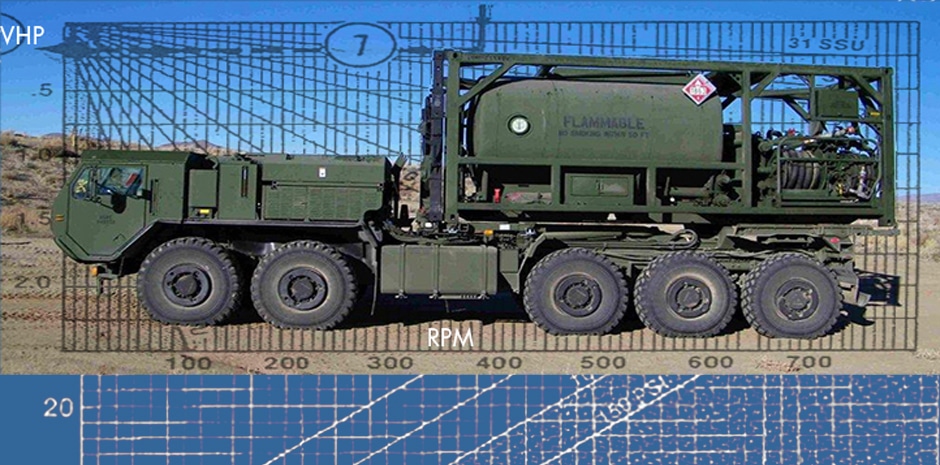

The Granco pump design results in a lower maintenance profile, easier installation, higher volumetric efficiencies, lower energy usage, and reversibility. It is easily adaptable to pump fluids from 32 ssu (water) to over 1,000,000 ssu (cold grease). These pumps are either truck mounted or stationary and can be driven by electric motor drives, gas engine drive, hydraulic motor drive, or belt drive. The same basic pump can easily pump thin fluids to the most viscous fluids without changing the design.

Competitive Pricing

GRANCO pumps are priced to be competitive with other general purpose positive displacement pumps. They are often less expensive than alternatives for handling specialty applications. GRANCO pumps’ quality, long lasting durability and lack of regular maintenance allows them to have an extremely low “Total Life Time” cost. It lasts much longer and has fewer maintenance requirements than less expensive pumps.