Tech & Specs

Download the full dimensions and performance chart here:

Dependable Operation

Unmatched Durability

Granco manufactures a full line of unique rotary positive displacement ball type pumps. In fact, it is the only ball type design being manufactured today. The simple ball and shaft design promotes durability because the pumping mechanism “floats” in the housing with no metal to metal contact. This design promotes years of durable, dependable service. The large rotating cavities provide slower speeds which maintains critical tolerances not seen in any other designs.

Adaptable Design

The unique design of the Granco pump provides a lower maintenance profile, easier installation, higher volumetric efficiencies, lower energy usage, reversibility, and easily adaptable to pump fluids from 32 ssu

(water) to over 1,000,000 ssu (cold grease). These pumps are either truck mounted or stationary and can be driven by electric motor drives, gas engine drive, hydraulic motor drive, or belt drive. The same basic pump can pump thin fluids to the most viscous fluids without changing its design.

Reversible Flow

Versatile Applications

Think Ni-Resist!

Materials of Construction

Temperature issues usually require Ni-Resist or cast iron and water based products need bronze. Granco can offer many solutions to problematic applications with the variety of materials available and in stock.”

Is Granco Right For You?

Usage Examples

Ready wherever you need them

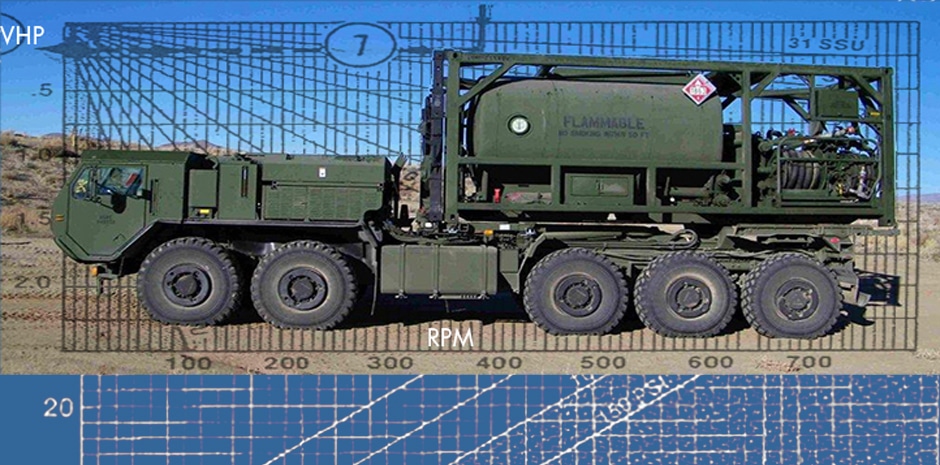

Granco has developed a new hydraulic motor mount for use on its entire line of pumps. The new flange mount provides direct drive mounting of the hydraulic motor permitting a more compact and rugged arrangement which eliminates a separate motor mount and the need to align the drive. On truck applications the power-take-off and universal joint drives are eliminated and replaced by the hydraulic lines from an engine driven hydraulic pump. For this reason, the Granco Truck-Mounted pumps can be located anywhere on the truck body and the controls placed where convenient. More than one pump can be easily installed, and with proper valving, the additional advantages of hydraulic drives can be used. Those advantages are infinite speed control, reversibility for two-way pumping, and pressure relief on the hydraulic side.

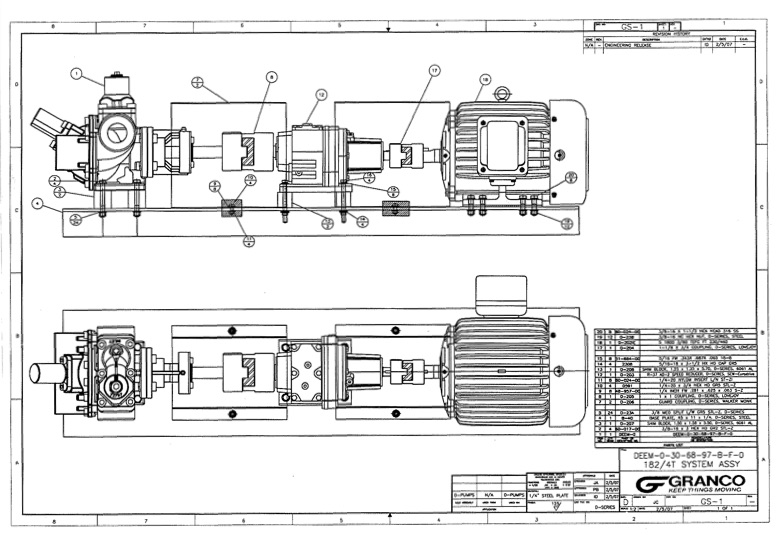

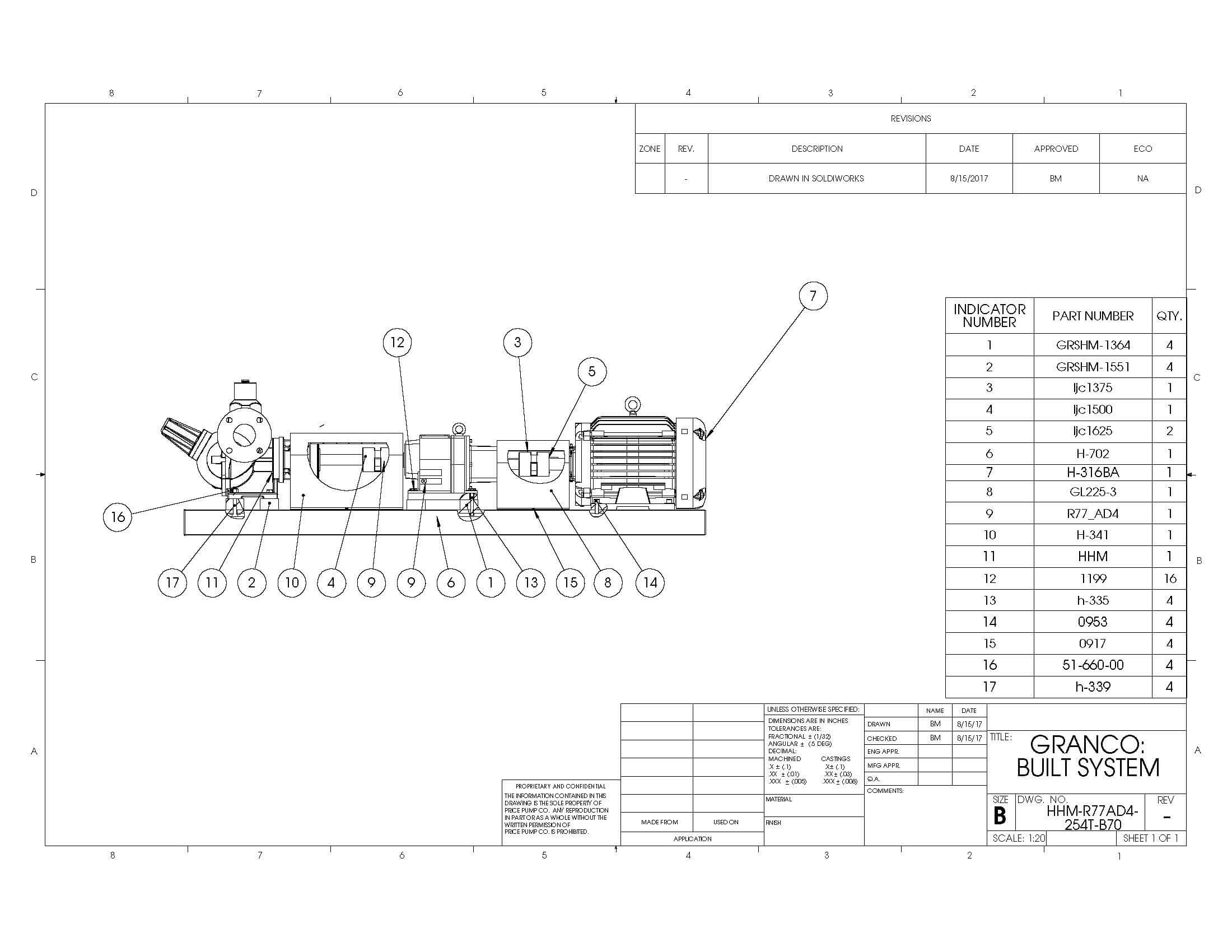

All units are securely mounted on a heavy steel base and easily adapted to any type of power source. The performance is smooth and quiet with no vibration when properly installed. All of Granco’s pump models have a rugged, cartridge-type outboard bearing and they are designed with two ports. Four port pumps are available upon request. Compare small space requirements and the efficient operation of our mounted units and you will find that Granco is your best buy in pumping equipment. All systems are engineered with the proper size motor and gear reducer directly driving the pump. The gear reducers used have totally enclosed reduction gears running in a smoothly in an oil-tight gear housing. The size of the motor will depend on the flow required, viscosity, temperature of the liquid, diameter and length of the discharge pipe along with the total dynamic head. All Granco pumps are available with gear motor drive, variable speed drive, torque limited drive and gasoline engine drive. Pictured is a typical system drawing produced for each individual system manufactured by Granco.

The HY-DRIVE pumping system features full reversibility of all Granco transfer pumps in your plant operation. A manual control for each transfer pump allows flow in either direction through the pump. By opening and closing valves, or switching hose connections in your system, the operator can have total control over the destination of the fluids in each individual tank. Savings are in initial costs since pre-engineered components allows us to custom design your drive system without the huge initial design cost. You save on operating labor cost since the centralized control of the entire system saves manpower and time. One man control is usually recommended. You save on operating costs since this system allows one or two pumps operating at once and the system adjusts itself to the conditions using only the energy called for by the system demand. In multiple pump systems quality concerns are solved by avoiding cross contamination in the final product by dedicating one pump for each individual tank. With only one large electrical motor and starter for the hydraulic power pack, the cost and complexity of make the system explosion proof if needed is dramatically reduced. Expansion for future growth is no problem since more pumps can be added to the entire system at minimal cost.

Granco Markets Served

(Stationary or Truck-mounted)

PETROLEUM RELATED PRODUCTS

Low Viscosity Hydrocarbons

- Diesel Fuels

- Unleaded Gasoline

- Jet Fuels (A/B)

- Aviation Gasoline

- Kerosene

- Solvents

Medium Viscosity Oil Products

- Lube Oils

- Gear Oils

- Multi-grade Lubricants

- Auto Transmission Fluids

- Waste Oil

- Base Petroleum Products for Blending

- Hydraulic Oils

High Viscosity Petroleum Products

- Grease

- Creosote

- Bunker C

- Coal Tar

- Crude

- Coal Tar

- Asphalt

- Asphalt Emulsions & Mixtures

- Heat Transfer Fluids

Industrial Markets

Paint & Varnish

- Highway Striping Epoxy Resins

- Oil Base Paint

- Water Base Paint

- Resin Base Paint

- Paint Recirculation

B. Glues, Adhesives & Chemicals

- Resins

- Polymers

- Latex

- Monomers

- Epoxy Resins

- Alkyd Resins

- Plastisols

- Slurries

- Aldehydes

- Ketons

- Acetone

- Acids

- Alcohols

Water & water-Based Liquids

- Water

- Seawater

- Bilge Water

- Oil Skimmers

*Due to poor lubricity of water and water based liquids, their applications are not strong recommendations, as wear may be excessive. Increased clearances due to wear can cause poor performance.

However, some GRANCO applications have been successful.

Bronze pumps or bronze rotors are recommended for their self-lubricating tendencies and resistance to corrosion.

Soaps & Detergents

- Concentrated Soap

- Diluted Soap

- Concentrated Detergents

- Diluted Detergents

*Granco pumps have been used for both concentrated and diluted soaps and detergents, where excessive foaming and aeration must be avoided.

Process Applications( Ni-Resist Pumps)

Low Viscosity

- Hot Oils

- Cooking Oils(deep fat frying)

- Acids

- Caustics

- Fertilizers

Medium Viscosity

- Vegetable Oils

- Soybean Oil

- Corn Oil

- Fish Oil

- Cottonseed Oil

- Coconut Oil

- Hot Tallow

- Animal Feed

High Viscosity

- Molasses

- Corn Syrup

- Liquid Sugar

- Fats & Tallows

- Liquid Feed

- Animal Feed

- Crude Petroluem

- Bunker C

- Epoxy Resins

Process Applications (Ni-Resist Pumps)

A. Petroleum Applications (Sour Crude)

B. Marine (Seawater and Bilge)

C. Chemical Processing (Acids and Alkalines)

D. Food Handling (Vinegar, Liquid Sugar)

E. Fertilizer (Ammonium Sulphate)

F. Pulp & Paper(Suphates and Sulfides)

Want More Details?

Download the specs and dimensions chart to see all the various specs available. Don’t see what you need? Get in touch with us so we can make it for you!